Post by VBF-12 Gosling on Jul 20, 2018 9:00:39 GMT -5

Okay, so what are these AMAD things.

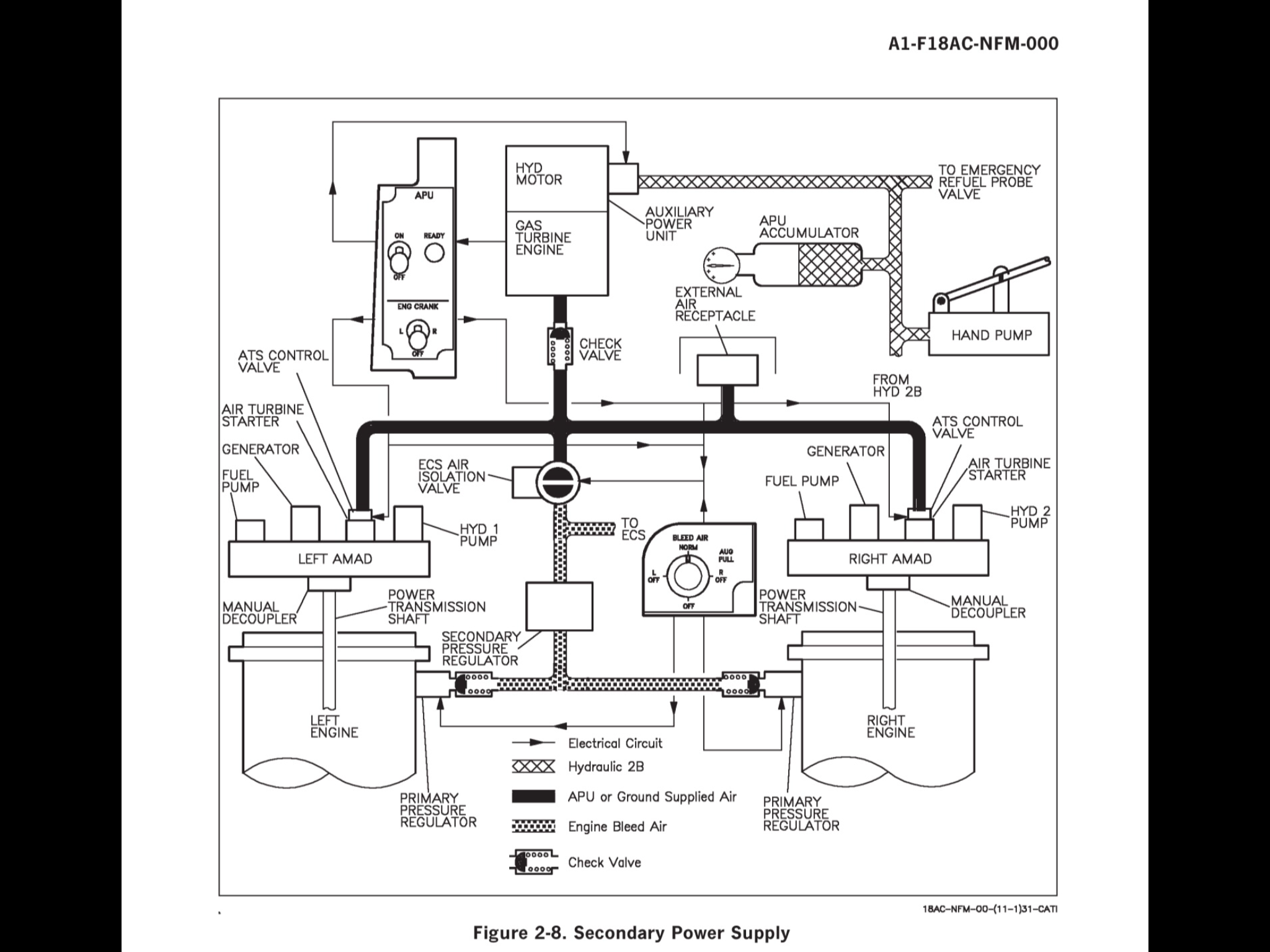

Well the Airframe Mounted Accessory Drive (AMAD) are part of the Secondary Power Supply System and are Gearboxes attached to the engines that work both ways. They power systems like the hydraulics but also spin the engines for start... Let’s take a look:

So the Key part is the centre with Black Pipes. This is compressed air either feeding or coming from the engines.... There are a number of ways to start the engines but they are all based on air pressure spinning up the turbines to 18% before cracking open the Throttle (RShft Home / RAlt Home) to introduce fuel and ignite.

APU START

Unusually, the “APU”, which is the “Gas Turbine Engine” (Centre Top), is started via the Hyd2A system, the APU Accumulator discharges to spin the “Hydraulic Motor” (Centre Top) which sins the APU turbines. The aircraft fuel supply and electrics (battery) for ignition is automatically controlled.

The APU is providing sufficient air pressure once the Green Light is on. IF the “Hydrauic Accumulator” Pressure is low (APU ACCUM) can be charged via the “Hand Pump” if required. When the APU control circuitry detects 2 generators running and will automatically shut down the PUSH 1 minute later. attached that supplies the Hyd2A system with pressure for pre-engine start essential hydraulic ancillaries. However, its main purpose is to generate air pressure to spin the first engine up to enough speed to light it.

ENGINE START

So the air is provided by the APU However the air could be provided by a ground unit plugged in to the “External Air Receptacle” (in the centre). The “Air Turbine Starter” (ATS) spins up the engine and it lights once fuel is injected by moving the throttle.... Normally the second engine is started the same way. However, once up to Ground Idle, the engine is generating air pressure so can be used to start the second engine. With the APU off, the circuitry will copen the ATS Control Valves and ECS Air Iswlation Valve (centre), to allow air from the engine bleed (at the “Primary Pressure Regulator”) into the main air line . The APU is then blocked off at the “Check Valve” (Centre Top). This engine bleed air is then used to start the second engine.

BLEEDS

The bleeds are a controlled by valves in the Primary Pressure Regulators. It is a controlled leak and reduces the engines ability to provide full power. Hence the electrical control vita the rotary switch (Centre).

ELECTRICS

The Electrics basically provides the information for the start system to know which air is available and thus which valve to open and close.

AMAD DRIVE

THe AMADs are driven directly via the engine Power Turbine Shaft (PTS). However with a failed engine, the bleed from the good engine can be used to spin the dead side AMAD. Infact the APU could be started to run that AMAD also.

Of course, the AMADs do a lot more of course as each has a Hydraulic Pump, an AC Generator and a Fuel Pump. Systems that will be covered later...

ECS

Finally, the Environmentatl Control System is supplied with the engine bleed air as it is hot. However, there is a risk of smoke and fumes in teh cockpit as a result. Hence the need to select teh O2 directly if there is I a bleed air problem.

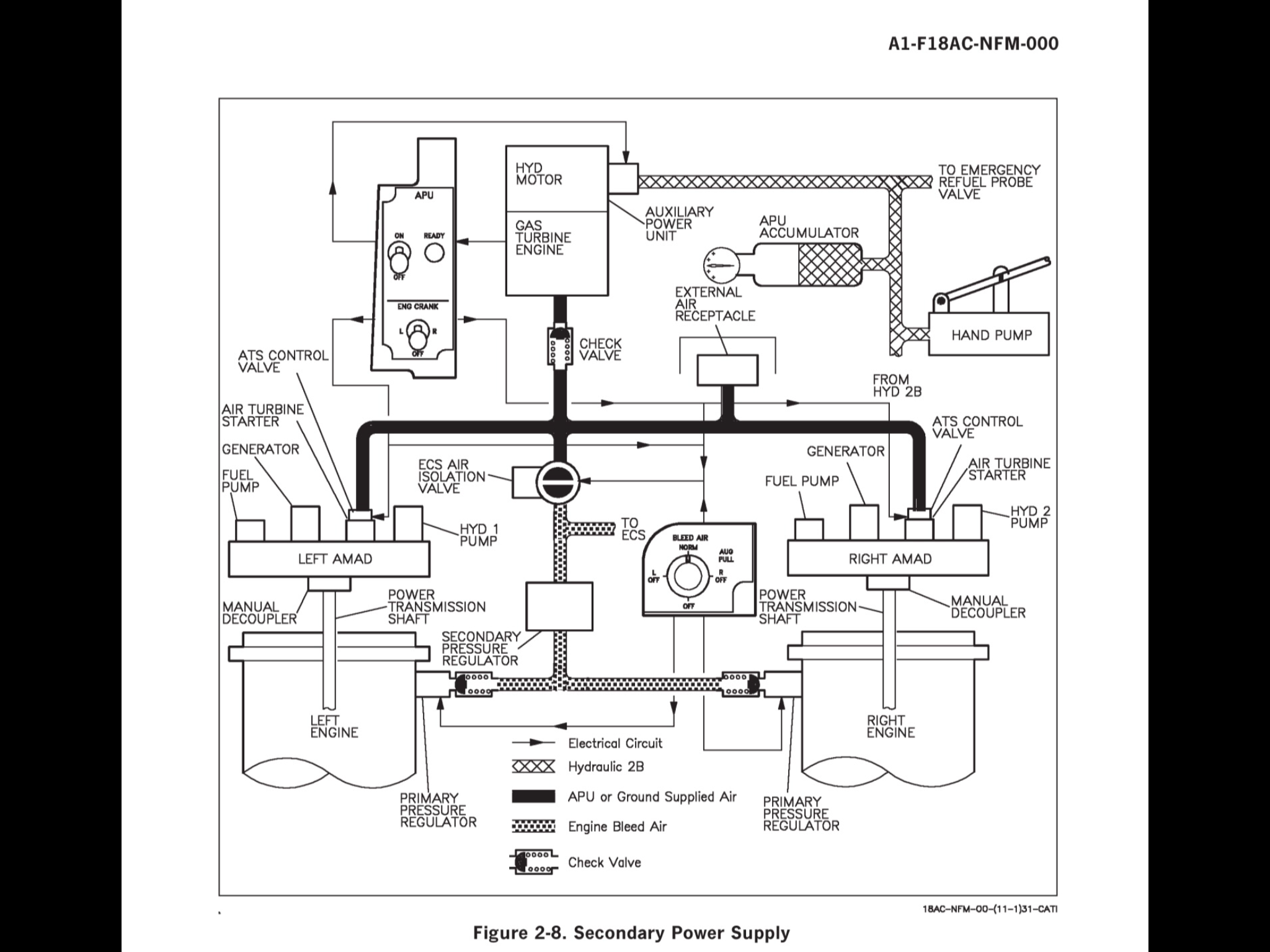

Well the Airframe Mounted Accessory Drive (AMAD) are part of the Secondary Power Supply System and are Gearboxes attached to the engines that work both ways. They power systems like the hydraulics but also spin the engines for start... Let’s take a look:

So the Key part is the centre with Black Pipes. This is compressed air either feeding or coming from the engines.... There are a number of ways to start the engines but they are all based on air pressure spinning up the turbines to 18% before cracking open the Throttle (RShft Home / RAlt Home) to introduce fuel and ignite.

APU START

Unusually, the “APU”, which is the “Gas Turbine Engine” (Centre Top), is started via the Hyd2A system, the APU Accumulator discharges to spin the “Hydraulic Motor” (Centre Top) which sins the APU turbines. The aircraft fuel supply and electrics (battery) for ignition is automatically controlled.

The APU is providing sufficient air pressure once the Green Light is on. IF the “Hydrauic Accumulator” Pressure is low (APU ACCUM) can be charged via the “Hand Pump” if required. When the APU control circuitry detects 2 generators running and will automatically shut down the PUSH 1 minute later. attached that supplies the Hyd2A system with pressure for pre-engine start essential hydraulic ancillaries. However, its main purpose is to generate air pressure to spin the first engine up to enough speed to light it.

ENGINE START

So the air is provided by the APU However the air could be provided by a ground unit plugged in to the “External Air Receptacle” (in the centre). The “Air Turbine Starter” (ATS) spins up the engine and it lights once fuel is injected by moving the throttle.... Normally the second engine is started the same way. However, once up to Ground Idle, the engine is generating air pressure so can be used to start the second engine. With the APU off, the circuitry will copen the ATS Control Valves and ECS Air Iswlation Valve (centre), to allow air from the engine bleed (at the “Primary Pressure Regulator”) into the main air line . The APU is then blocked off at the “Check Valve” (Centre Top). This engine bleed air is then used to start the second engine.

BLEEDS

The bleeds are a controlled by valves in the Primary Pressure Regulators. It is a controlled leak and reduces the engines ability to provide full power. Hence the electrical control vita the rotary switch (Centre).

ELECTRICS

The Electrics basically provides the information for the start system to know which air is available and thus which valve to open and close.

AMAD DRIVE

THe AMADs are driven directly via the engine Power Turbine Shaft (PTS). However with a failed engine, the bleed from the good engine can be used to spin the dead side AMAD. Infact the APU could be started to run that AMAD also.

Of course, the AMADs do a lot more of course as each has a Hydraulic Pump, an AC Generator and a Fuel Pump. Systems that will be covered later...

ECS

Finally, the Environmentatl Control System is supplied with the engine bleed air as it is hot. However, there is a risk of smoke and fumes in teh cockpit as a result. Hence the need to select teh O2 directly if there is I a bleed air problem.